Driving next-gen battery innovation

We’re leading the commercialization of silicon anode batteries to power reliable, safe, and high-performing applications.

WHAT WE DO

Delivering the highest energy density battery cells on the market

Our advanced silicon anodes allow for greater energy and power density, pushing the boundaries of what’s possible—without compromising performance.

Play Video

Go faster and further

Experience battery technology like never before.

Highest energy density

Delivering batteries with up to 450 Wh/kg, our batteries offer unparalleled energy density, enabling longer range and extended runtime across demanding applications.High discharge rate

Our batteries provide exceptional power density, supporting applications that demand rapid, high-power output without compromising efficiency.Ultra-fast charging

Our batteries can charge 0% to 80% in as little as six minutes, addressing one of the major concerns for electric mobility—the lengthy charging process.Long cycle life

Our batteries are engineered to maintain performance through 1,300 full charge cycles—providing reliability and efficiency over an extended lifespan.Wide operating temperature

Designed for versatility, our batteries perform reliably in extreme temperatures from -30°C to 60°C, ensuring consistent power delivery across diverse environments.Safety and reliability

Our batteries have passed rigorous safety tests, including the U.S. military's nail penetration test, and the globally recognized UN38.3 certification for safe transportation of lithium-ion cells.SOLUTIONS

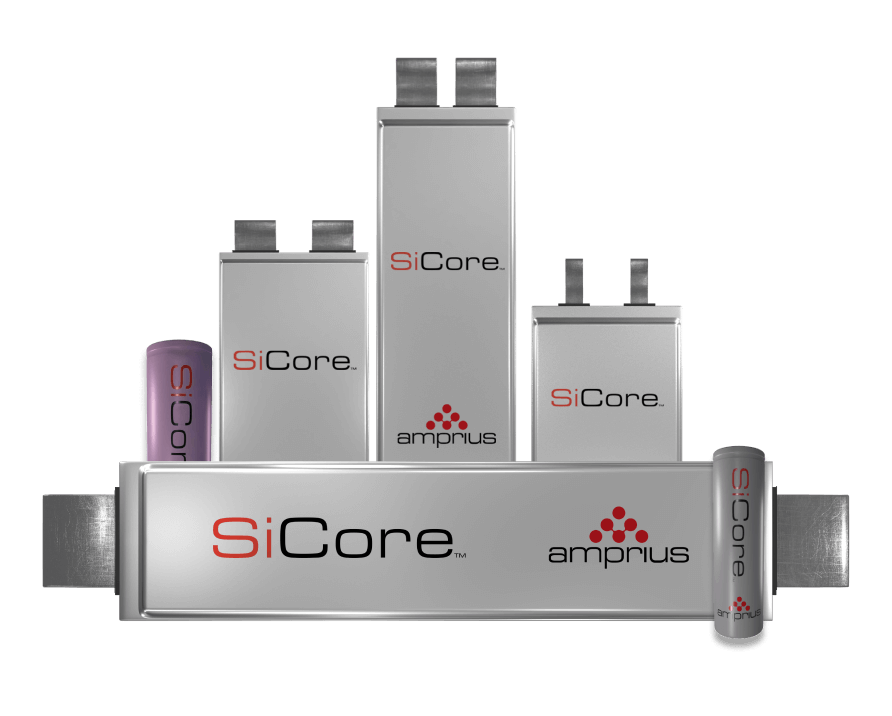

Harnessing the power of silicon

Our portfolio of high-performance silicon anode batteries delivers superior discharge performance and energy efficiency, powering the next wave of innovation across electric mobility, drones, aircraft, wearables, and emerging markets.

Silicon is the key to unlocking next-level battery performance, storing up to 10 times more lithium than graphite. Our advanced silicon battery technology delivers unmatched energy and power with proven long-lasting performance.

Industries

Built for high-performance applications

Prioritizing extended range and power capabilities, our battery cells power diverse industries.

Let's connect

Discover how silicon anode batteries can boost your application performance.

Get Started