Unlock new career opportunities with us

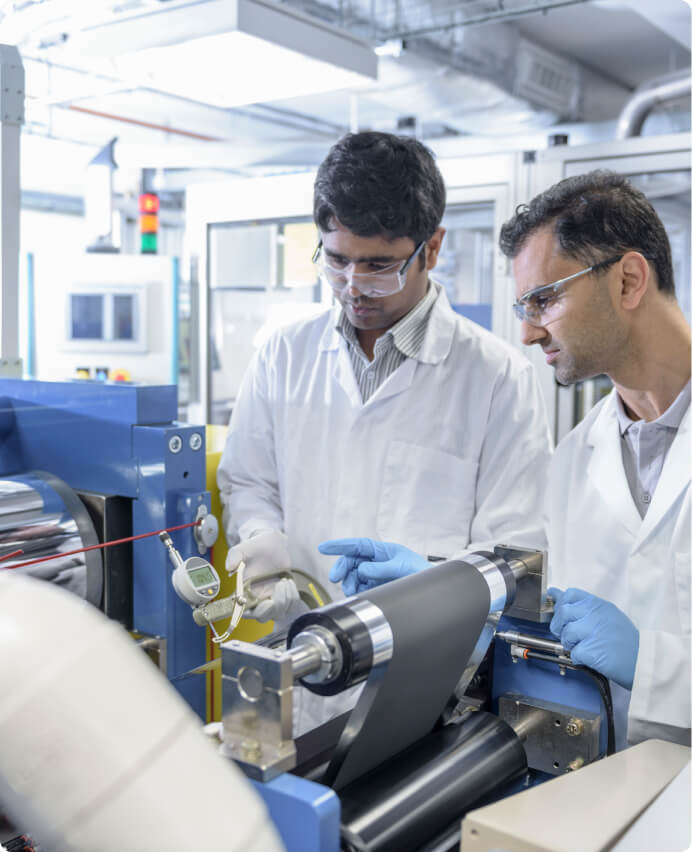

We’re pioneering the next generation of battery technology to improve people’s lives. If that sounds exciting to you, then you’re in the right place.

See Opportunities

Level up at Amprius

Join a team where innovation drives real-world impact. At Amprius, we offer exciting career growth opportunities and a collaborative environment focused on excellence.

Job opportunities

Join our growing team. Explore open positions in our different departments.

Benefits and perks

We provide a range of benefits to support your professional growth and personal well-being.

Our headquarters

1180 Page Ave, Fremont, CA 94538

Located in the heart of Silicon Valley, our cutting-edge R&D and pilot manufacturing facility offers a dynamic environment with unmatched opportunities for innovation and professional growth.

View Location

Innovate at the Forefront of Battery Technology

Work on cutting-edge silicon anode lithium-ion technology that is revolutionizing industries. From electric vehicles to aerospace, your contributions will power the future.Collaborate in an Impact-Driven Environmen

At Amprius, you'll work alongside passionate, talented teams that solve complex challenges in a highly dynamic environment, pushing the boundaries of what’s possible.Grow with Amprius and Elevate Your Career

Join a company with opportunities to work across diverse teams and projects. At Amprius, you’ll continuously develop your skills in a culture of learning and collaboration.

Let's connect

Discover how silicon anode batteries can boost your application performance.

Get Started